How to Choose the Right Lift for Narrow Warehouse Aisles

Narrow aisles make simple jobs feel complicated. You are not only trying to reach a higher shelf or fix a ceiling light. You are trying to do it without blocking traffic, without forcing constant repositioning, and without turning every small task into a mini project. If you want to choose the right lift for narrow warehouse aisles, start with how your space actually works day to day, not the tallest number on a brochure.

This guide walks through the selection factors that matter most in tight indoor spaces. It focuses on practical fit: aisle width, turning space, task type, operator count, and how often the lift will be used. By the end, you should be able to match the lift type to the work, then send your internal shortlist in the right direction.

Why Narrow Warehouse Aisles Change Lift Selection Rules

In a wide facility, you can “make it work” with almost any lift. In a narrow aisle warehouse, small differences turn into daily friction. A lift that technically fits may still be a headache if it cannot turn cleanly, park precisely, or leave space for people and carts to pass.

Narrow aisles also amplify workflow problems. If your team needs to pause picking every time the lift enters an aisle, the lift becomes the bottleneck. And if the lift feels awkward to position, operators start improvising, reaching too far, or rushing the setup. Those habits reduce safety and slow the job down anyway.

So the main rule is simple: in tight indoor spaces, choose for access and positioning first, then think about height.

Start With Aisle Width and Turning Space

Most selection mistakes begin with measuring the wrong thing. “Aisle width” on a drawing is not the same as the clear space you actually have after pallets, end caps, guardrails, and random daily clutter show up.

Measuring Clear Width vs Nominal Aisle Width

Walk the narrowest route the lift must travel, not the cleanest aisle in the building. Measure the tightest point, including any door frames, corners, and rack uprights that stick out. Pay attention to transitions as well. A lift that fits between racks might still struggle at the doorway into the warehouse or at a turn into a backroom corridor.

If you operate in mixed-use zones, measure those too. Many warehouses have a narrow maintenance path behind a packing line that becomes the true constraint.

Why Turning Radius Matters More Than Lift Width

Straight-line fit is only step one. Turning and positioning are where time disappears. If your lift needs multiple back-and-forth moves to line up with a target point, the aisle stays blocked longer and the task feels slower than it should.

Think of turning space as the “hidden width” your lift needs. Even a slim machine can be frustrating if it cannot rotate and park where the work actually happens.

Single-Person or Two-Person Work?

Before you compare lift types, decide how work at height is typically handled in your operation. This one factor often determines whether a compact platform is enough or whether you need a larger deck.

When a Single Person Lift Makes Sense

If most tasks are handled by one technician, a single person lift can be the cleanest solution. Typical examples include point inspections, quick checks, and short maintenance jobs. You bring up a small tool bag, finish the task, and move to the next location.

This is exactly where a vertical mast lift tends to shine. If your use case fits that profile, review a dedicated guide to a vertical mast lift for narrow indoor spaces before you commit to a larger platform style machine.

When Platform Space Becomes Necessary

If tasks regularly involve cartons, bulky parts, or two people working together, platform space becomes more than a comfort feature. It becomes a productivity feature. A larger platform can hold tools, parts, and sometimes a second operator, which reduces trips up and down and makes longer tasks less tiring.

As a rough reality check, if your operators often say “I need a place to set this down,” you are already drifting away from single-person access tools.

Task Type Matters More Than Maximum Height

“Lift heights” and “height of a lift” are easy to compare. Real job flow is harder, but it is what determines whether the purchase feels right after the first week.

Point Tasks vs Continuous Work

Point tasks happen at a single location: one ceiling sensor, one light fixture, one camera, one sign. They are short and precise. Continuous work happens along a line: a row of lights, a long section of cable tray, repeated label changes along a rack bay.

Point tasks reward slim access and fast positioning. Continuous work rewards platform comfort and fewer resets.

Inspection, Maintenance, and Stock Handling

Inspection and light maintenance usually favor compact machines, especially in narrow spaces. Stock handling and repetitive overhead work often favor stable platforms, because you may need room for cartons, handheld devices, or small parts.

This is why “different lift types” exist. They solve different kinds of lifting operations, even if the working height range overlaps.

Comparing Common Lift Types for Narrow Aisles

This section is a quick map, not a full deep dive. If you want a detailed head-to-head breakdown, you can review the full comparison here: vertical mast lift vs scissor lift.

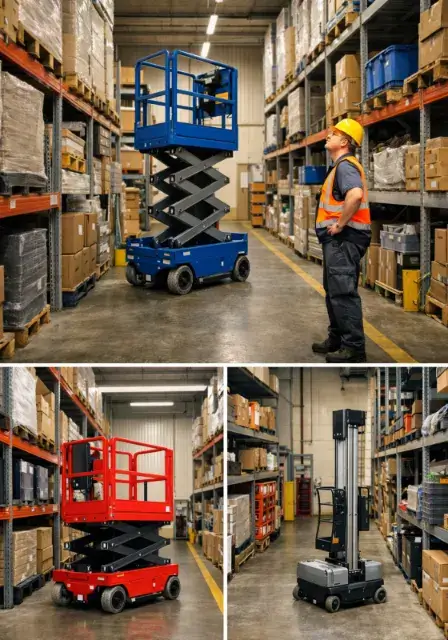

Mini Scissor Lifts

Mini scissor lifts are built around a stable platform and a scissor mechanism. That platform space is the main advantage. It supports longer tasks, more comfortable posture, and better load handling for tools and light cartons. Many models are designed for indoor use, with sizes of lifts that fit between racks while still giving a useful deck.

The trade-off is footprint. Even compact units can require more turning space. In very tight layouts, the lift may fit but feel slower to position.

Vertical Mast Lifts

Vertical mast lifts use a mast-type structure to move the operator straight up. They are often chosen for narrow routes, corners, and point tasks. Their slim profile makes them easier to move through doorways and tight corridors, and precise positioning is usually faster once you get used to the controls.

The trade-off is platform space and lift capacity. A mast lift is typically a single-person solution, best for tools and small parts rather than cartons or two-person work.

How Often Will the Lift Be Used?

Frequency changes everything. A lift used twice a month can be slightly inconvenient and still be fine. A lift used ten times a day becomes part of your production rhythm, so small annoyances become major costs.

Occasional Access vs Daily Use

For occasional access, you can prioritize simple movement, storage convenience, and quick setup. For daily use, you should prioritize speed of positioning, operator comfort, and how disruptive the lift is to aisle traffic.

A lift that is slightly larger but faster for the real task may beat a narrower lift that requires more resets. The “right” answer depends on the pattern of your work, not the catalog.

Fatigue, Speed, and Workflow Disruption

Fatigue is a quiet cost. Repeated awkward posture, constant repositioning, and limited space to work all reduce speed over a shift. In high-traffic aisles, workflow disruption is just as important. A lift that blocks an aisle for five extra minutes per job can turn into hours per week.

If your warehouse has a rhythm, choose the lift that interrupts it the least.

Indoor Constraints You Should Not Ignore

Indoor environments have constraints that outdoor job sites do not. Ignoring them is how a lift that “should work” ends up parked and rarely used.

Doorways, Elevators, and Floor Conditions

Doorway clearance is a common surprise. So are tight turns near stairwells, packing stations, and backroom corridors. If the lift needs to move between floors, elevator access becomes part of the selection logic.

Floor conditions matter too. Smooth concrete is ideal. Ramps, thresholds, and uneven transitions require more caution. A lift that is stable on flat floors may feel less forgiving during transitions.

Storage Space When the Lift Is Not in Use

Where will the lift live when it is not working? In small warehouses, storage is always tight. If parking the lift blocks a fire exit, a staging lane, or a packing area, it will create daily frustration and people will avoid using it.

A lift that fits your work but does not fit your building layout is still the wrong lift.

A Simple Decision Framework for Narrow Warehouse Lifts

At this point, you have enough information to make a practical call. Use these quick questions to choose the right lift for narrow warehouse aisles without overthinking it:

- Is your tightest route a narrow corridor with turns and doorways?

- Are most tasks point inspections or short maintenance jobs?

- Is the work usually done by one operator at a time?

- Do tasks require carrying cartons or larger parts at height?

- Will the lift be used occasionally or every day?

If your answers lean toward tight routes, point tasks, and one operator, a vertical mast lift is usually the stronger match. If your answers lean toward repeated work, tools plus cartons, and longer time at height, a mini scissor platform often feels better.

Lift Selection Guide for Narrow Warehouse Aisles

| Selection Factor | Mini Scissor Lift | Vertical Mast Lift |

|---|---|---|

| Typical Aisle Width | Narrow but needs turning space | Very narrow, minimal clearance |

| Operator Count | One or two people | Single person lift |

| Platform Space | Large, stable working platform | Compact basket or small platform |

| Load Handling | Suitable for tools and light cartons | Best for tools and small parts |

| Task Type | Continuous or repeated work | Point tasks and inspections |

| Working Comfort | Better for longer tasks at height | Better for short, precise access |

| Maneuverability | Stable, but wider footprint | Slim profile, easy positioning |

| Best Use Case | Stock handling, maintenance, installations | Lighting checks, inspections, tight corners |

If your decision points toward a platform-based machine, browsing a mini scissor lift for narrow warehouse aisles can help you compare options without locking into a single model too early.

Conclusion

There is no perfect lift for every narrow warehouse. The right choice depends on how your aisles behave in real life, how tasks are performed, and how often the lift will be used. Start with clear width and turning space, then decide whether your work is mostly single-person point tasks or longer platform-style jobs that involve load handling. When you make the lift match the workflow, work at height becomes routine instead of disruptive.

How JQLIFT Helps You Match Lift Type to Narrow-Aisle Work

JQLIFT designs indoor access equipment with the practical limits of narrow warehouses in mind. Rather than treating “small” as a scaled-down version of outdoor machines, the product focus centers on compact footprints, stable lifting structures, and straightforward operation for real indoor routes. For platform-based tasks such as maintenance and repeated overhead work, JQLIFT scissor lifts emphasize usable deck space and steady vertical travel. For tight access and point tasks handled by one technician, vertical mast lift options support precise positioning and single-person work in confined areas. If you are building a lift shortlist, JQLIFT’s lineup makes it easier to match lift type to aisle width, task pattern, and day-to-day workflow without forcing your warehouse to adapt to the machine.

FAQ

Q1: What is the best lift for narrow warehouse aisles?

A: The best lift depends on how narrow the route is, how much turning space you have, and whether tasks are point inspections or longer platform work. Match the lift type to the task pattern first.

Q2: Can a scissor lift work in tight indoor spaces?

A: Yes, especially mini scissor lifts designed for indoor use. The key is confirming turning space and positioning room, not only straight-line aisle width.

Q3: When should you choose a vertical mast lift instead?

A: Choose a vertical mast lift when you need a slim profile for doorways and tight turns, and when most tasks are short point jobs handled by one operator.

Q4: How narrow is too narrow for a scissor lift?

A: There is no single number. Aisle width, turning radius, and the ability to park at the work point all matter. Measure the tightest real route, including corners and doorways.

Q5: Does lift height matter as much as aisle width?

A: Height matters, but aisle width and turning space often matter more indoors. A lift that reaches the height but cannot position efficiently will slow work and block traffic.