How to Choose the Right Hydraulic Scissor Lift for Your Warehouse? (2025 Buyer’s Guide)

Efficiency in a warehouse? It is not just about forklifts zipping around. It is about getting up high. Maybe you are changing bulbs at 10 meters. Maybe you are grabbing stock from the top shelf. You need the right tool.

Pick the wrong machine, and you are in trouble. Buy one that is too big? It won’t fit through the door. Buy one that is too weak? It just sits there. This guide cuts through the noise. We will look at height, hydraulics, and how to find a mobile scissor lift for warehouse use that doesn’t blow your budget.

1. Assess Your Warehouse Environment (The “Where”)

Construction sites are messy. Warehouses are controlled. That is a big difference. Don’t look at a catalog yet. Go measure your space.

Aisle Width and Doorways

Grab a tape measure. Check the narrowest aisle. You don’t want a traffic jam because the lift is too wide. You might need a model built for tight spots. And check the doorways. Managers forget this all the time. Can the lift roll through a standard door when it is down? If the scissor mechanism is too tall, you are trapped in one room.

Ground Conditions

Look at the floor. Is it flat concrete? Good. You don’t need expensive “rough terrain” tires. You need solid, non-marking tires. They keep the floor clean. No black marks.

2. Differentiate Working Height vs. Platform Height (The “High”)

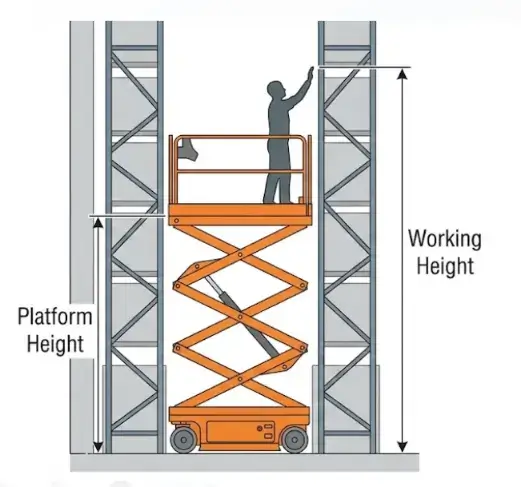

Here is where people waste money. “Platform Height” and “Working Height” are not the same. If you mix them up, you buy too much machine.

Platform Height is where your feet are. Working Height is where your hands reach. That is usually 2 meters (6 feet) higher. Racks are 8 meters high? You don’t need an 8-meter platform. A 6-meter one is fine. Figure out your main scissor lift purpose. Is it fixing the ceiling? Picking orders? Match the height to the actual job.

3. Calculate Load Capacity and Platform Size (The “What”)

One guy going up? Rarely. It is usually two people, a heavy toolbox, and maybe a heavy part.

Standard lifts handle 230kg to 450kg. Count the total weight. If you ignore the average weight of scissor lift limits, the machine stops. The lifting power is real—it uses the same physics as a heavy-duty hydraulic scissor jack lifting a car—but it has limits.

Look for “Extension Decks.” These are huge. They slide out. You get an extra meter of reach. You can reach over pallets on the floor to get to the racks. You don’t have to move the base.

4. Why Hydraulic Drive is Ideal for Warehousing

Electric Drive or Hydraulic Drive? For indoors, hydraulic is usually the smart move. It is reliable. It costs less.

Simplicity and Power

Think about the tech. It works just like a robust hydraulic scissor jack you see in a garage, but bigger and safer. The fluid gives smooth power. Electric drive motors are complex. They cost a lot to fix. Hydraulic systems? Simple.

Maintenance

You need to know the difference between hydraulic and electric lift maintenance. Hydraulic is easier to fix. Mechanics understand pumps and valves. This keeps the lift servicing requirements low over the years.

5. Budget Considerations: Performance vs. Cost

Let’s talk cash. Western brands are expensive. It shocks people. But look around.

You don’t need used gear. You can import new equipment. Reputable hubs offer high specs for less money. Worried about the budget? The savings are real. Read Why Import Aerial Work Platforms from China? to see the numbers.

6. Essential Safety Features for Indoor Use

Safety isn’t just a rule book. It keeps people alive. Check the specs. Verify the protection.

Critical Systems

Modern scissor lift safety features are more than just a rail. You need “Pothole Protection.” Floors have bumps. This system stops the lift from tipping. Look for “Tilt Sensors” too. If the floor is slanted, the lift stays down. These are standard scissor lift safety features. They help you meet osha aerial lift safety requirements.

Emergency Controls

Power cuts out? You are 10 meters up. You need a way down. Models like the compact hydraulic scissor lifts have emergency valves. Check the platform controls. Make sure they are easy to use. Make sure there is a stop button.

Scissor Lift Selection Checklist

Use this list. Do it before you sign the check.

- Environment: Indoor slab or outdoor gravel? (Get the right tires)

- Height: Did you calculate Platform Height or Working Height?

- Load: Can it lift two people? (Treat it like a hydraulic scissor jack—don’t overload it).

- Safety: Are all the scissor lift safety features there?

- Power: Will the battery last a full shift?

Ready to look at models? View the complete catalog of warehouse lifting equipment to match your needs.

Conclusion

The right lift makes things safe. It makes things fast. A two-hour job becomes a twenty-minute job. Don’t guess. Measure the warehouse. Count the workers. Get the specs right.

JQLIFT: Engineering Excellence for Your Warehouse

Reliability matters. JQLIFT delivers it. Located in Hangzhou’s industrial heart, JQLIFT (Hangzhou Jiequ Machinery Manufacturing Co., Ltd.) makes hydraulic aerial work platforms. We aren’t a trading company reselling boxes. We are the manufacturer. We focus on precision. We make the ZSF series scissor lifts and heavy boom lifts for warehouses all over the world.

We control production. From cutting raw manganese steel to robotic welding and load testing. Quality is built in. Every unit meets CE and ISO9001 standards. For you, JQLIFT means a direct line to the factory. Transparent pricing. Custom colors or voltages. Dedicated spare parts. Choosing JQLIFT means partnering with people who understand modern logistics.

FAQ

Q1: What is the main difference between a scissor lift and a boom lift? A: A boom lift goes “up and over.” Good for hard spots. A scissor lift goes straight up. But it holds more weight. It gives you a bigger platform.

Q2: Can I charge an electric scissor lift with a standard outlet? A: Yes, usually. Most have a built-in charger. Plug it into a wall socket. Do it overnight so it is ready in the morning.

Q3: Do I need a license to operate a scissor lift in a warehouse? A: Mostly, yes. You need certification (like OSHA training). It proves you know the controls. It keeps everyone safe.

Q4: How often does a hydraulic scissor lift need maintenance? A: Check it visually every day. A mechanic should service it every 6 to 12 months. It depends on how much you use it.

Q5: What happens if the battery dies while the platform is up? A: Don’t panic. Lifts have a manual emergency lowering valve at the base. Someone on the ground pulls it. You come down safely.