How Much Weight Can a Hydraulic Scissor Lift Hold?

When you look at a lift spec sheet, the first number that often catches your eye is the weight it can carry. You want to know if it will safely hold people, tools and materials without drama. The tricky part is that there is no single “standard” number for all lifts. Capacity changes with size, structure and how the lift will be used. This guide gives you a clear way to think about that question, so you can pick a model that fits your real jobs, not just the catalog.

What Determines the Load Capacity of a Hydraulic Scissor Lift?

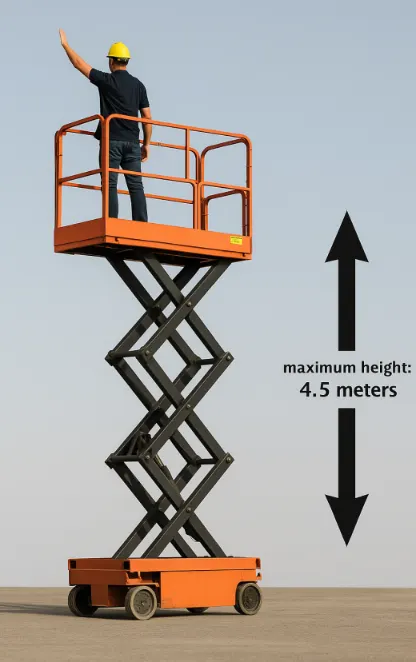

A hydraulic scissor lift load capacity is decided by the design, not guessed later on site. Engineers set the rating after checking the frame, scissor arms, platform size, hydraulic cylinders and even the kind of floor the lift will stand on. For you, that number is the maximum safe total of people, tools and materials on the platform at full height, written in kilograms or pounds on the data plate.

Platform Size and Structure

In simple terms, a bigger and stronger platform can take more weight. Many compact indoor lifts on the market carry roughly 230–450 kg, while larger units can go from about 500 kg up to 1,000 kg or more, depending on their class. That range covers one or two people plus tools for indoor work, and it can stretch to heavy parts in industrial plants. What matters is that your typical load stays inside the stated rating with room to spare.

Typical Load Capacities You May See in the Market

When you compare spec sheets from different makers, the numbers can start to look the same. In fact they cover quite a wide field. Compact electric scissor lifts often sit at the lower end, with platform capacities in the 227–450 kg band. Heavy fixed scissor tables and special multi-stage units for industry can reach well above a tonne.

From Compact Indoor Units to Heavy Duty Models

For everyday building and warehouse work, many sites choose a small hydraulic scissor lift. It is usually narrow enough for aisles, yet still rated for two people plus boxes of parts or light equipment. At the other extreme, big industrial lifts can support pallets, steel parts or other dense loads, but they often stay in one place and serve a fixed line or station. When you read “typical capacity” online, always check if the example is a mobile work platform or a stationary lifting table, because the numbers can be very different.

Why Exceeding Rated Capacity Is Dangerous

It is easy to think “this time it is only a bit over the limit”, especially when a job runs late. The rated figure, though, already includes a safety factor from the designer. When you go over that, you remove that buffer and change how the machine behaves at height.

What Happens When You Overload the Lift

Too much weight can make the platform sit lower than normal, lean to one side or respond slowly to lift and drive commands. Over many cycles, extra load adds stress to pins, arms and hydraulic parts and raises the chance of cracks or leaks. Guidance on safe use also notes that the rating is for the total of workers, tools and materials together, not just the heaviest item. In the worst case you risk tipping if the extra weight sits on one corner, or damaging a floor slab that was never chosen for that higher point load.

How to Choose the Right Load Capacity for Your Job

To choose well, start from your work, not from a random number. Think about how many people stand on the platform during a busy shift and what they bring with them. A box of tiles, a coil of cable or a small motor all add up fast when you count them honestly.

Simple Steps to Match Capacity to Your Tasks

A simple method is this: add the weight of each worker, then add a fair total for tools and materials for a typical job. If that comes close to the rating, move up one size so you are not working near the limit every day. Leave some margin for days when loads run heavier than planned. If most of your work is indoors with racks, lights and ducting in narrow spaces, looking at a hydraulic scissor lift made for compact aisles gives you a practical balance between safe capacity and easy movement.

Inside the Work of Hangzhou Jiequ Machinery Manufacturing Co., Ltd. (JQLIFT)

Hangzhou Jiequ Machinery Manufacturing Co., Ltd. (JQLIFT) is an aerial work platform supplier based in East China with many years of design, production and sales experience. The company focuses on equipment for safe work at height, including scissor lifts, vertical mast lifts, aerial order pickers and other lifting tools that serve warehouses, factories and service sites in many regions. JQLIFT pays close attention to compact electric and hydraulic lifts for indoor use, where low noise, clean operation and steady platforms matter every day. Its product series and case projects show a clear focus on real job needs, such as narrow aisles, low ceiling work and frequent maintenance cycles, rather than just chasing the biggest figures on paper.

FAQ

Q1: How much weight can a normal hydraulic scissor lift hold?

A: Many mobile lifts for indoor work carry roughly 230–450 kg on the platform. Larger or special units can handle from about 500 kg up to 1,000 kg or more, depending on size and use.

Q2: Does the rated capacity include the people on the platform?

A: Yes, it does. The rating is for the total of workers, tools and materials together, so your own body weight always counts in that number.

Q3: Is it okay to run slightly over the rated load?

A: It is not a good idea. The capacity already has a safety margin built in, so “a bit extra” eats into that margin and raises the risk of damage or a tip.

Q4: Do indoor scissor lifts usually have lower capacity than outdoor ones?

A: Often they do. Indoor electric models focus on being narrow, light and quiet for smooth floors, while large rough-terrain lifts outside can be heavier and carry more load.

Q5: How much spare capacity should you plan for?

A: A simple rule is to pick a lift where your normal total load sits well under the rating, for example around 70–80% of the stated capacity. That way daily work stays in a comfortable band without pushing the lift hard every time.